How to choose a 3D printer?

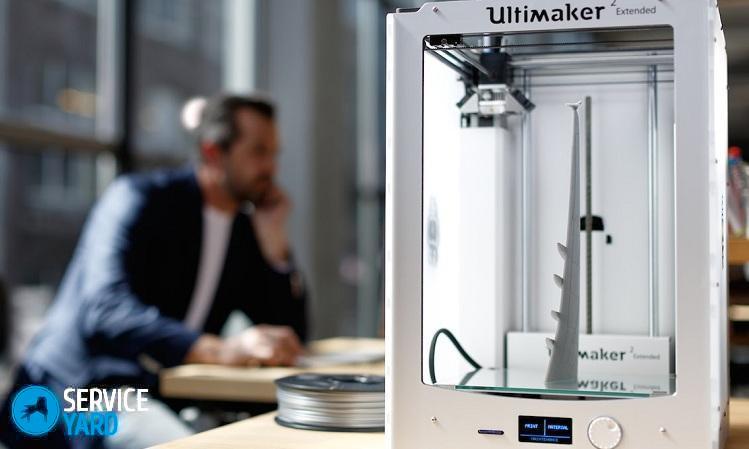

Today, products with 3D 3D image are becoming more popular. Accordingly - if you decide to open a small home business, the acquisition of a three-dimensional printer will be a real find for you. Thanks to this wonderful technique, you will be able to realize most of your ideas, while it’s pretty good to earn extra money. Therefore, you need to take the purchase of such an aggregate with all responsibility and know how to choose the 3D printer correctly so that it not only pays off, but also brings you profit.

to contents ↑How to choose a 3D printer?

To begin with, you should pay attention to the fact that, regardless of the type and model you are considering, all 3D printers are selected solely for general technical indicators. In order to understand which one you need, you should carefully consider and analyze each factor that affects the quality of further operation of this unit. Thanks to this, you will be able to evaluate and understand what functions you will need and what you will not need at all during operation. Next, we consider in more detail the main characteristics that you need to pay attention to when choosing a 3D printer.

Minimum layer thickness

Minimum layer thickness is a key feature of the printer’s detailed features. This is due to the fact that most of these machines operate on FDM technology.

Important! FDM is a technology for modeling various objects by layering a molten filament.

This parameter indicates the volume of the produced thread. Therefore, when choosing a printer, one should take into account the fact that the smaller the thickness of the thread, the better and more valuable the finished product.

Important! When choosing a 3D printer, try to pay attention to models in which the used layer thickness is 50-200 microns.

In addition, it should be noted that a 3D printer will not always produce the required layer thickness. The vibration factors of this parameter include:

- The movement of air inside the machine itself;

- A sharp change in temperature in the room;

- The presence of various gaps in the design of the printer;

- Poorly adjusted distance between the printing platform and nozzle.

The speed of movement of the print head directly affects the quality of the resulting product: the slower the head moves, the slower the plastic thread is fed, respectively - the finished product will be much better.

Important! Pay your attention to the model of printers, which are regulated by the speed of movement of the print head and the feed rate of plastic, regardless of each other.

What materials does the 3D printer work with?

- Considering that the 3D printer works in FDM mode, PLA plastic is most often used for work. This is due to the fact that this material is the most undemanding in operation, has a high resistance to deformation, quickly cools when blowing. Also, PLA plastic can be used to create various decorative products both at home and in business.

Important! PLA plastic has an organic composition, so it quickly decomposes within a few years.

- As for the creation of mechanical parts, the production of various molds and bodies for casting, as well as parts of physical supports, ABS plastic should be used. This is a fairly wear-resistant material, which in relation to PLA plastic is much more reliable and durable. The only drawback of ABS plastic is that it cools down rather slowly.

Important! The 3D printer market is constantly being improved and modified, respectively - each time new materials and compositions appear, such as PVA, Hips, PETT, nylon and rubber. Therefore, before purchasing a particular model of 3D printer, make sure that this unit works with most of the above materials.

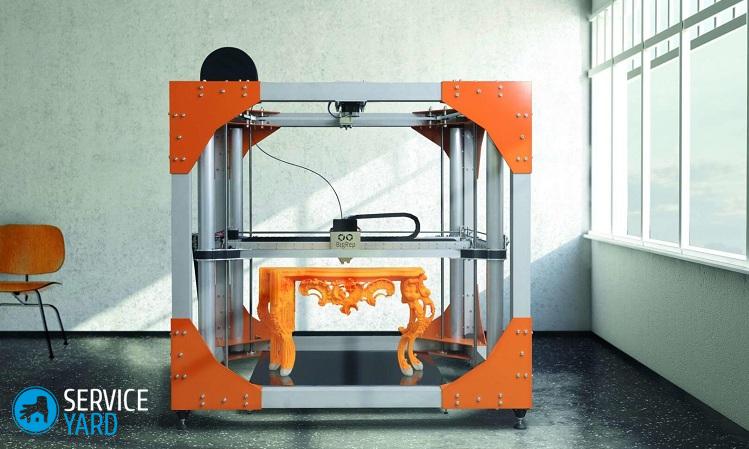

Design features

In order to understand which 3D printer to choose for home or business, it is very important to consider the design features of the model. The basis of the printing process is the extruder and platform, which are fixed and moved exclusively along the axes and guides.

Important! The extruder moves only on a horizontal plane, but the platform - both horizontal and vertical, depending on the print level.

In addition, it should be borne in mind that the differences between the design of such machines do not affect the original quality of the product at all. Print quality depends solely on the material of parts and assembly. But for the stability and durability of the 3D printer, the total number of parts and the gaps between them is directly responsible.

The structure of the extruder - print head

The principle of its operation is to extrude heated plastic threads with a thickness of 1.75-3 millimeters, which are in an almost liquid state on the surface of the platform. Therefore, the structure of the print head consists of several parts at once. On both sides of the thread are two small wheels:

- one - clamping, which is adjustable;

- the second is located directly in front of the head itself and is controlled by a stepper motor, which feeds the thread directly into the extruder.

After that, the material will enter the nozzle and exit directly to the surface with the already melted plastic.

Easy print setup

For the manufacture of bulk products at home or in industry, mainly two types of software are used:

- Computer modelling;

- 3D printer management.

Important! Files of all models are converted to STL format. In this format, further processing of images of future products, which are already recorded in the desired form, is performed.

Before choosing a 3D printer for home or for production, it should be borne in mind that in some models the necessary parameters for the future product are set automatically, and in others it is necessary to pre-adjust and set the following boundaries:

- Temperature conditions of the head and platform;

- Extruder speed;

- Plastic feed rate;

- Layer thickness;

- The thickness of the substrate and wall;

- Intensity and operating conditions of the fan;

- Support setup.

Important! Also during operation, it should be taken into account that plastic is subject to deformation. Therefore, before starting the printing process, you need to correctly configure all the programs in order to avoid further damage to the product during the many hours of operation of the printer.

Print Speed and Accuracy

Accuracy, speed and print quality are the most important criteria that you should pay attention to first of all, regardless of the general structure of the printer. For example:

- For the manufacture of large and complex products, you do not need a machine with high printing accuracy. In this case, it is better to turn your attention to high-speed models.

- If you need to print small parts or small mechanisms, then the accuracy of the printer comes first. Unfortunately, the speed of such machines is much lower.

Important! Unfortunately, universal 3D printers do not exist yet. However, you can choose exactly the model that, according to its characteristics, will best meet your requirements.

3D printer features

Considering that the technology of three-dimensional printing is actively developing today, more and more new models of 3D printers appear every year. For example:

- The latest novelty of this technique is units that can print in three colors - they can create colored objects.

- There are machines that can print products without connecting to a PC. They work offline, and the necessary data for printing can be transferred using a portable drive or (if there is a built-in module) via Wi-Fi and the Internet.

Country of manufacture

When choosing 3D printers, one of the most important factors is in which country it is manufactured or assembled. The operational qualities of this unit directly depend on this. The main manufacturers of 3D printers are:

- USA and European countries. Unfortunately, they are imported into our country in small batches, so the prices of such models are quite high. In addition, due to the lack of official representatives, there is a problem with service and a shortage of necessary spare parts in case of breakage.

- China. Despite its low cost, in this case, the build quality and further operational properties suffer.

- Russian production. Such models are inferior in quality to European ones, but much better than Chinese devices. Their main advantage is the constant availability of spare parts in case of breakage and the possibility of full service.

The best of the best

We bring to your attention models of 3D printers that have repeatedly proven themselves exclusively on the positive side.

Original Prusa i3 MK2

This is one of the best models that is used both among beginners and amateurs in the field of volume printing.

Its main features are:

- New heating table MK42;

- Improved firmware

- Printed surface made of PEI plastic;

- Thanks to the original design of the nozzle, printing speed is increased;

- Integrated Z-axis;

- Improved design;

- Automatic calibration;

- Printing speed 40-60 millimeters per second;

- Minimum layer height 50 microns.

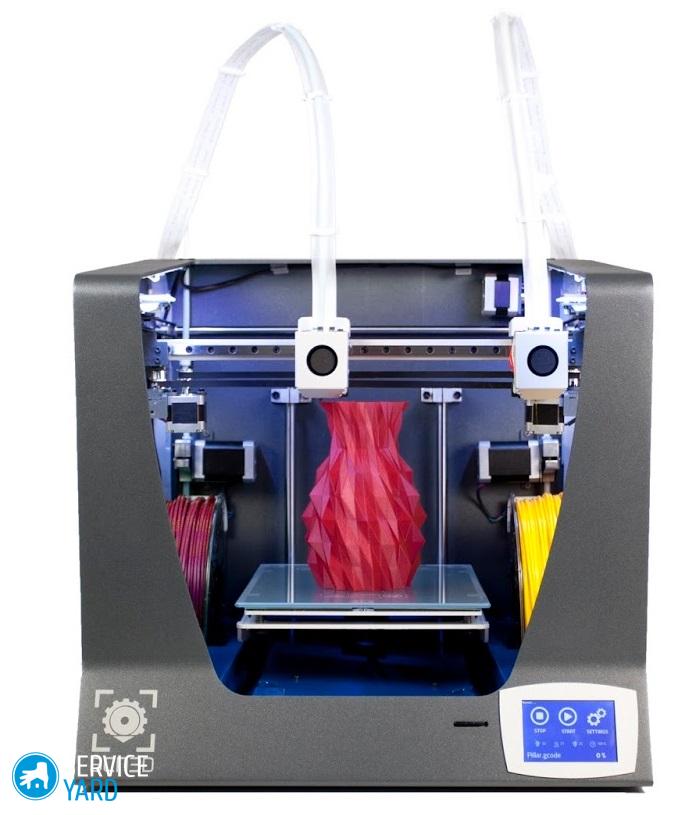

BCN3D Sigma

The main advantage of this model is the presence of two heads, which help to avoid deformation during a color change. In addition, in this case, you will be able to print two identical objects at the same time.

The main characteristics of BCN3D Sigma include:

- XY accuracy 125 microns;

- The minimum layer height is 50 microns, and the maximum is 300;

- The presence of a built-in control panel;

- Heated platform;

- The diameter of the thread is about 3.00 millimeters.

Formlabs Form 2

This is the only and best 3D stereolithographic printer that has SLA printing technology. It uses a powerful laser, built-in Wi-Fi module, touch display and a fairly extensive print area. Also, software has been specially developed for this model, thanks to which it is possible to construct an object more accurate and of high quality.

PowerSpec 3D Pro

This is a fairly budget printer that is manufactured in China. Its main advantages are a double extruder, durability and fast printing speed. The only drawback is that this printer model is somewhat outdated, so it will not work for printing complex and trendy objects.

Kossel

This is the only printer that is based on modern Delta technology. Its main advantage is the automatic leveling function, as well as the ability to print with a resolution of 30 microns. Such models differ from the others in their characteristics and functionality, print accuracy and long-term operational properties.

to contents ↑Stock footage

As you can see, the choice of a 3D printer is a complex and responsible process, because, in addition to the fact that such a technique is quite expensive, the quality of printed objects also depends on it.Putting into practice the recommendations of our experts, you will be able to purchase exactly the model that will become an excellent assistant for both home and professional use.

- How to choose a vacuum cleaner taking into account the characteristics of the house and coatings?

- What to look for when choosing a water delivery

- How to quickly create comfort at home - tips for housewives

- How to choose the perfect TV - useful tips

- What to look for when choosing blinds

- What should be running shoes?

- What useful things can you buy in a hardware store

- Iphone 11 pro max review

- Than iPhone is better than Android smartphones