What furniture is made of: modern materials

In the arrangement of the apartment, one of the main roles is played by the situation. The beauty and harmony of the home depends on the choice of a bed, table, chest of drawers. Before buying a headset in the bedroom, it is better to find out what furniture is made of, what materials are used. Then it will be much easier to get a high-quality, safe, functional cabinet that will last a long time.

Raw materials for the manufacture of furniture

Manufacturers demonstrate a variety of materials for furniture production. The choice of buyers depends on the available budget, the style of the apartment. The variety of textures used by the masters allows you to create durable, safe cabinets, tables, chairs. And also realize the most daring design ideas

Before you stop at the selected headset for the bedroom, you should make sure that it is harmless to health. This is especially true for furniture for the children's room. Then it is necessary to determine the reliability, wear resistance of materials, because this affects the life of the wardrobe. Modern furniture manufacturers use expensive and cheap raw materials. However, low price does not always mean poor quality. There are furniture designs made of glass, metal, plastic. But more often, the basis of furniture is wood or its derivatives obtained as a result of processing. These include:

- solid wood;

- veneer;

- Chipboard;

- Chipboard;

- MDF.

All these materials are similar to each other, but have fundamental differences. Understanding what furniture is made of, you can use it in different places and situations. Natural wood, for example, is customary to use for furnishing rooms for children, kindergartens, schools.

Natural wood

Natural wood products do not lose popularity due to environmental friendliness and high quality. You need to select them carefully, taking into account the features of the array. For the production of furniture, shields are used. They are solid or glued from battens. The presence of knots is undesirable, as they impair the quality of the finished cabinet. Annual rings also deserve attention; they can also talk about the quality of wood.

Exclusive designs are created from shields. There are the concepts of "array" and "wooden furniture." The latter is made of wood boards and inferior in quality to solid wood. An array is a natural material, strength, beauty, durability. The cabinetmaker will easily select the right kind of wood for the manufacture of the necessary structure. Characteristics of the materials used by furniture makers:

- Spruce - due to the large number of knots, the tree is difficult to process. Spruce bars firmly stick together, they do not warp, but they are quite fragile. They are often used to make plywood sheets.

- Larch - not subject to decay, stronger than all other varieties. But the material is very dense, so it weighs a lot.

- Walnut - a young tree gives soft wood, which allows you to easily cut out any bends of decorative finishes. Initially, the nut has a light tone, but it darkens very much with time. It also gains great hardness.

- Pine - the texture is clearly visible, has a light shade. Wood is relatively inexpensive, easy to process. This is the most used variety. Density and water repellent are lower than larch.

- Oak is a valuable species of wood. Products from it are durable, durable. Oak is durable and flexible at the same time. Often curved parts are made from it.Bog oak is one of the most expensive varieties.

- Ash - has a warm, light color. Furniture made of it lasts a long time; cracks do not appear.

- Birch - works well. The breed is soft, but heavy.

- Beech - in hardness is not inferior to oak. The tree is well suited for any treatment, but fungus easily appears on it.

Also in the manufacture of furniture used some varieties of fruit trees, acacia, maple and others. A good master knows how to make a chair or chest of drawers from solid wood with his own hands according to his own plan.

Fiberboard or MDF

MDF is a type of wood slab, which is made from sawdust. In strength, it is almost not inferior to wood. The material is characterized by quality and increased resistance to moisture, steam. Its surface is almost perfectly smooth. It is quite flexible, which allows you to create curved facades and other details. Material is a godsend for furniture makers. Thanks to him, the boldest ideas of designers are embodied

The price of this raw material exceeds the cost of chipboard and chipboard, so only facades are produced from it. For the manufacture of the internal parts of the cabinet, other plates are used. MDF is made by hot pressing using natural lignin glue and melamine converted urea resins. This gives a low evaporation of formaldehyde comparable to natural wood. The material has drawbacks, although it has significantly more advantages. Positive qualities of MDF:

- easy to process;

- resistant to fungus;

- more dense than wood;

- natural, environmentally friendly;

- increased moisture resistance;

- tolerates temperature differences;

- low price.

The characteristics of MDF are almost entirely composed of positive points, but it also has drawbacks. Negative material properties:

- Do not heat above 70 ° C;

- easy to damage.

The wood plate does not crumble during processing, so the facades are often finished with patterns, carvings. It is just as easy to cut holes for fittings in it, and the mounting screws hold very firmly. MDF is a material with excellent properties, which is popular in construction, furniture manufacturing. It is a good choice for the manufacture of bedroom, kitchen sets and other cabinet furniture. Technical advantages make the product durable and beautiful. And the price of this material is not too high.

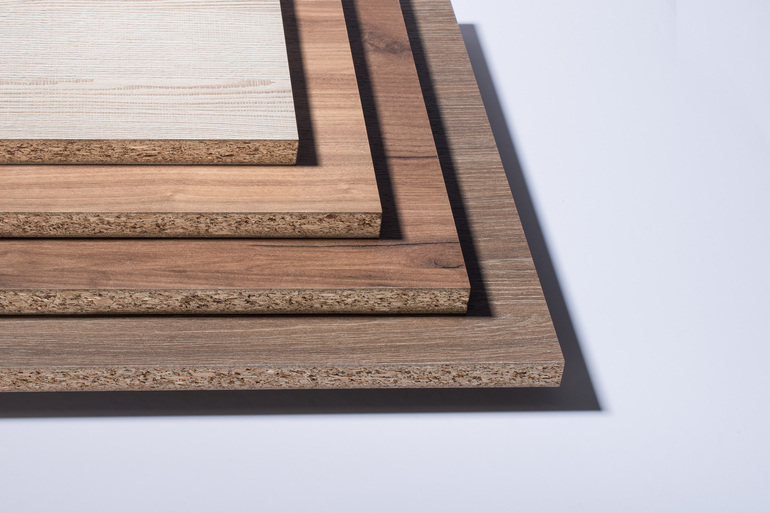

Particleboard, chipboard and fiberboard

Chipboard is obtained by hot pressing wood chips mixed with resins of non-mineral origin. Composite material is produced in various shapes, colors, textures. Therefore, it is universal, suitable for almost any design style. To give a wood slab texture use:

- veneer;

- laminate;

- melamine;

- PVC

- postforming.

Particleboard costs less than MDF, but inferior in quality. Chipboards are heavy and non-moisture resistant. Screws are not securely attached to them. Material can poison the air with harmful substances. It happens that parts made of chipboard are placed in places that are not visible. Such furniture can imperceptibly harm health. To avoid the evaporation of formaldehyde, the surface of the plate is varnished or painted. Three grades of chipboard stand out:

- The first - in the production of using chips of one tree. The plate has a smooth texture, it is covered with a laminate or veneer.

- The second - the surface of the plate has slight damage, scratches. Defects are not reflected in the technical specifications.

- The third - has serious drawbacks. It is applied only in rough works.

Chipboard - the so-called laminated chipboard. This variety eliminates some of the disadvantages of particleboard. The surface of the material is finished with a polymer film or painted with moisture-resistant varnish. As a result, the plates become more durable. The chipboard also has a low production price. Due to these qualities, furniture, including bedrooms, is most often made from a laminated panel.Thanks to various coatings, the panel becomes similar to metal or natural wood.

Lamination prevents the release of formaldehyde. But the film does not cover all the surfaces of the plate. Often the ends remain open, the edges do not laminate. This can be eliminated by covering them with paint or by gluing an edge tape. After drilling the panel, the holes are also better sealed.

Fiberboard - wood-fiber board. Obtained by hot pressing or drying a sheet of small wood fibers. From the fiberboard make the rear walls of the wardrobe, as well as the bottom for the drawers. Fibreboard is fragile and very easy to damage. But due to the small thickness they are flexible, easy to cut. The panels are fastened with glue, small studs, and self-tapping screws.

Models from metal, plastic

Metal is a durable material that is used in furniture manufacturing. Metal furniture has taken its place in homes and offices. It turns out reliable, designed for long-term operation. The price of such items is quite low. Often metal is combined with other materials and models for the home, park, and garden are produced.

Metal furniture is popular, fits well with the interior styles of hi-tech, minimalism. When using metal elements with glass, a feeling of airiness, lightness is created. Metal furniture legs significantly extend the life of sofas, beds, and armchairs. This cold material goes well with leather, textiles, and plastic.

Forged products are very popular. They are reliable, durable. The price of such beds, tables and chairs is high, but they look solid. Especially decorated with glass ceramics, mosaics, marble. There is an alternative to forging - metal furniture. She weighs less, looks modern. They make it from steel, aluminum. Such items, in combination with stone, fabrics, glass, look original. There are folding models. They are easy to clean, suitable for summer cottages.

Plastic furniture weighs little, durable, multi-colored, its price is low. She is actively used in public places, apartments, country houses. Now plastic items are especially popular with lovers of country holidays. Plastic models are very diverse. These are tables, chairs, chairs in a cafe. Dressers, cabinets, coffee tables in the houses. And also shops, chaise lounges, a swing on a seasonal dacha. Advantages of plastic:

- the surface can imitate any coating;

- variety of designs, colors;

- easy to store, transport, as the parts are collapsible;

- products are functional, practical, serve for a long time.

There are many advantages of plastic objects in the interior. But there are also disadvantages:

- decorate only modern interior styles;

- fragile, does not withstand heavy loads, high and low temperatures;

- forms toxic substances when heated.

Foreign manufacturers of Turkey and Italy make plastic furniture on a metal basis. Such designs are quite reliable and look decent. Despite the shortcomings, plastic is popular because of its practicality and low price.

Glass products

The usual material for the manufacture of furniture was glass. In modern interiors, it is designed to expand the boundaries of space, to make it light and bright. Glass models visually weightless, create the illusion of free space. Together with the fashion for mirrors, glass elements came to furniture production. And these are not only cabinet doors. From glass make:

- bar counters;

- countertops;

- kitchen aprons;

- coffee tables;

- whatnots.

For the manufacture of furniture used tempered glass with a thickness of 10 to 30 mm. Fasten parts by gluing, fusion. Slices and surfaces are ground, polished, which makes them safe. Such items can even be used in rooms for children. There are many ways to decorate glass surfaces:

- decoration with stones, rhinestones;

- sandblasting;

- giving the effect of dullness or tinting.

Glass - the material is natural, safe, does not cause allergies. With visible fragility, such furniture is durable and can withstand loads of up to 300 kg. But if the glass breaks, it will break into safe fragments or, as in the triplex system, will linger in a special gasket. If you combine it with wood, metal, plastic, it will give the interior modernity, lightness.

Understanding what furniture is made of, you can buy a quality wardrobe, table. They will be safe and will last a long time.

- How to choose a vacuum cleaner taking into account the characteristics of the house and coatings?

- What to look for when choosing a water delivery

- How to quickly create comfort at home - tips for housewives

- How to choose the perfect TV - useful tips

- What to look for when choosing blinds

- What should be running shoes?

- What useful things can you buy in a hardware store

- Iphone 11 pro max review

- Than iPhone is better than Android smartphones