Do-it-yourself making liquid stone at home

Do it yourself is not difficult to make liquid stone at home. Such material can be used in decoration and for the production of various decorative panels. It is made from a multicomponent polymer composition, which is based on polyester resins. This is a strong, durable material with an original appearance, it can be used in the decoration of private houses and apartments, designed in a different style.

Short description

Liquid durable stone is a modern finishing material, which, depending on the filler used, imitates various varieties of natural stone. Such a polymer is obtained by solidifying a multicomponent mixture, for the preparation of which artificial and natural fillers are used. It is possible to make liquid stone using various natural and artificial aggregates; hollow structures can also be made.

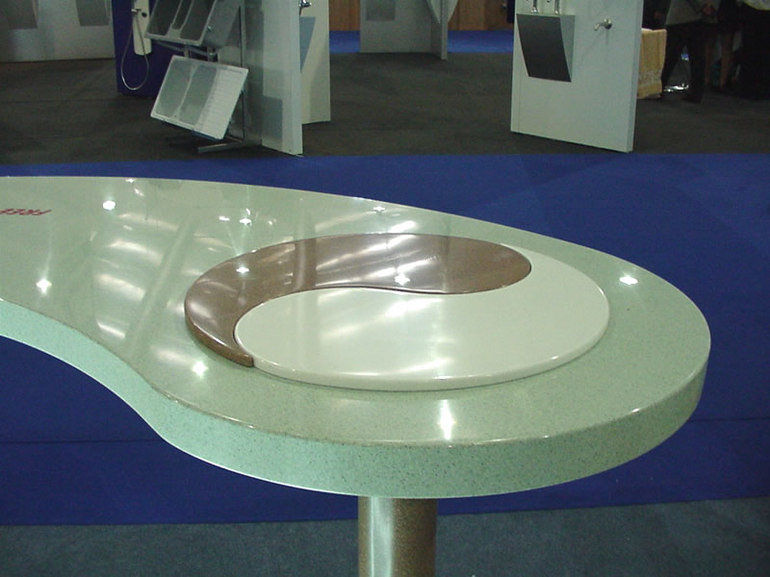

The material has many advantages, it was originally used for the manufacture of various decorative finishes, was used in construction, and subsequently stylish, beautiful, reliable, durable countertops and plumbing elements began to be made from it.

From it are made:

- bathtubs and sinks;

- kitchen worktops;

- steps for stairs;

- finishing decorative panels.

For the manufacture of stone, quartz, granite, marble and other granules or screening of durable materials with a diameter of a fraction of up to 2-3 mm are used. The fillers used are filled with polymer, which quickly hardens due to the action of hardeners, providing a characteristic perfectly smooth or rough surface that is durable, wear-resistant and has an attractive appearance.

Varieties and properties of the material

In its appearance, such a composite material is practically indistinguishable from a natural mineral. You can determine the artificial origin of the stone by tactile sensations. This polymer has a perfectly smooth, even surface. This material is warm and pleasant to the touch, which allows you to use it for the manufacture of various floor coverings.

Liquid artificial stone has a dense structure, which is resistant to external factors, significant temperature extremes and ultraviolet. The surface does not absorb dirt, which greatly simplifies the maintenance of countertops or tiles.

Currently, there are many varieties that differ in their polymer binder compositions, as well as the fillers used. Most often, an acrylic or translucent polyurethane adhesive is used to make the material. The filler used must have a dense structure with good adhesion, which allows for simultaneous strength with an interesting and attractive appearance.

Depending on the fillers used, such an artificial stone is usually divided into the following types:

- quartz;

- marble;

- acrylic;

- granite.

Each particular variety is selected depending on the desired color and type of such coating, as well as the required performance characteristics. The most durable polymers are those that use a polyurethane base and granite backfill.Varieties where marble or quartz are used as fillers have an original and unusual appearance.

Polymer Benefits

By its operational characteristics, reliability and durability, polymer stone is practically not inferior to granite and marble. The advantages of composites are usually attributed to their attractive appearance. With equal success, countertops and trim panels made of polymer stone can be used in the kitchen, in hallways and living rooms, designed in classic and modern design styles.

The advantages of the material include:

- strength and smoothness;

- ease of use;

- practicality of use;

- ductility of the coating.

Most often, kitchen worktops are made from this material, which are durable, retain their appearance for a long time, are characterized by wear resistance and moisture resistance. Qualitatively made and polished coatings will have an ideally smooth surface without microscopic pores; accordingly, maintenance of the worktop can be greatly simplified, which can be cleaned using conventional wet cleaning.

There is the possibility of additional coloring of the binder components, respectively, you can choose a stone of light shades or saturated black. Composites are resistant to ultraviolet radiation, such a countertop will retain its original original appearance for a long time, it will not fade in the sun, and even after 10 years it will look like new.

Liquid polymer stone is a fairly strong material, however, even after many years of operation, small scuffs and microscopic chips may appear on its surface. Such problems can be solved by additional polishing of the surface, which is done both manually and with the help of powerful grinders. Such work with the restoration of stone is not particularly difficult, therefore, every homeowner will cope with its implementation.

Used manufacturing technologies

Today, there are several stone manufacturing technologies, which makes it possible to produce high-quality and durable material that is guaranteed to last for many years. Thanks to the use of modern equipment and high-tech components, it is possible not only to improve operational characteristics, but also to perform composites, which in their appearance are practically indistinguishable from natural minerals.

The most widely used technology is the casting of polymer stone, the essence of which is the use of plastic molds with the required dimensions. The output is a monolithic panel, which requires subsequent processing and grinding. For the manufacture of artificial stone, you can use hand-made or purchased in stores forms made of plastic and other durable materials.

The casting technology used in the past had numerous advantages, but the products obtained were of high cost, which somewhat limited the distribution of stone made in this way. Subsequently, a method of spraying polymers appeared, which allows simultaneously to achieve an attractive surface appearance, significantly reducing the cost of manufacturing such a finish. A composite solution is applied to the prepared products using a spray gun, and then polishing is done manually or with a grinder.

Self-production can be performed both by casting technology and by spraying polymers. Working with liquid stone is not particularly difficult and when using high-quality components, including hardeners and adhesive with filler, it is easy to make durable and reliable panels that are guaranteed to last for many years.The undoubted advantage of using the spraying method is the ability to cover worktops with artificial compositions without dismantling, which greatly simplifies the repair work at home.

Liquid Stone Making

The manufacture of liquid stone at home is not difficult. Even with a minimum of experience, making a worktop made of liquid stone will not be difficult: you need to prepare the appropriate tools, take care of the presence of hardener, hot melt adhesive and decorative fillers used. You just need to remember that working with such material should be in protective rubber gloves and a respirator.

For such work, the following tools will be required:

- powerful compressor;

- electric drill;

- screwdriver and spray gun;

- hand mill and grinder;

- thermal gun;

- mixer nozzle on a drill.

You only need to prepare the appropriate components, the list of which will vary, depending on the desired appearance and characteristics of the stone.

For the manufacture of kitchen worktops sprayed with liquid stone, you will need the following:

- various colors;

- gelcoat;

- fiberglass and plasticine;

- fibrous or particle boards;

- hot glue and calcite;

- placeholders used.

Immediately before applying the material, a working mixture is prepared, for which a transparent gelcoat and aggregate granules are mixed in a consistency of 2 to 1. For high-quality mixing of the mixture, it is necessary to use a drill with a mixer nozzle. Subsequently, the hardener is carefully added to the composition, after which the mixture is applied manually or with the help of compressors to the base of the countertop or prepared chipboards.

Correct proportions

Very popular are varieties of artificial stone that imitate marble. The basis of this composite is a polyester resin with various mineral dyes and fillers. Such decorative kitchen worktops can be made using casting technology, and all that needs to be done is to properly prepare the mixture and use a suitable plastic mold in size. To perform the working composition, aggregates can be used: screening of jasper, crushed granite, onyx or natural marble.

When using acrylic or polyester resin, it is necessary to mix it with marble chips in a ratio of 4 to 1. Lime mortars, gypsum or cement can also be used as binders, however, it is the use of resin that allows the coating to provide maximum strength and its excellent decorative effect. Ready-made compositions can be found on sale, which greatly simplifies repair work, and all that is required is to prepare a solution and pour liquid stone into correctly selected forms.

Coating care

Liquid composite stone is a durable and moisture resistant coating, the care of which is not particularly difficult. It is possible to maintain the cleanliness of such countertops by wet cleaning, while using abrasive powders or various household chemicals is not recommended. The latter can lead to darkening and cloudiness of the surface, which forces subsequent polishing of the coating.

This polymer, unlike natural stone, does not withstand severe temperature changesTherefore, it is not recommended to put hot pots on such a countertop or kitchen table. This can lead to the appearance of noticeable influxes, which are extremely difficult to get rid of.

If necessary, restoration of the stone can use grinders with nozzles of various abrasiveness. Such work is not particularly difficult, polishing pastes can be used, which not only eliminates scuffs and chips, but also returns the coating to its original appearance and brightness of colors. Manual polishing using emery paper of various degrees of graininess is possible.

- How to choose a vacuum cleaner taking into account the characteristics of the house and coatings?

- What to look for when choosing a water delivery

- How to quickly create comfort at home - tips for housewives

- How to choose the perfect TV - useful tips

- What to look for when choosing blinds

- What should be running shoes?

- What useful things can you buy in a hardware store

- Iphone 11 pro max review

- Than iPhone is better than Android smartphones