Installation of tiles in a wooden house on a wooden floor

The need to combine different materials often arises in construction, for example, laying ceramic tiles on a wooden floor in a wooden house. The process features are studied before starting work in order to avoid future operational troubles. The quality of installation depends on the arrangement of the base.

General concept

The technology of facing with ceramic ceramics has been developed for a long time, but in the case of wooden floors, there are several distinctive features that are worth paying attention to. Sometimes it is not necessary to remove the coating, in other cases it is necessary to replace not only the coating, but also the structural elements.

In wooden houses, the most common floor on the logs, while at the base of the floor there is a base:

- frame-panel or frame;

- log;

- lumber.

Ceramics is becoming an increasingly affordable material due to its high performance. Tiles on the floor in a wooden house are laid not only in corridors, kitchens or hallways, but also used in rooms with high humidity. Moisture resistance, strength and ease of cleaning ceramics allows its use in the coating of bathrooms, saunas and baths.

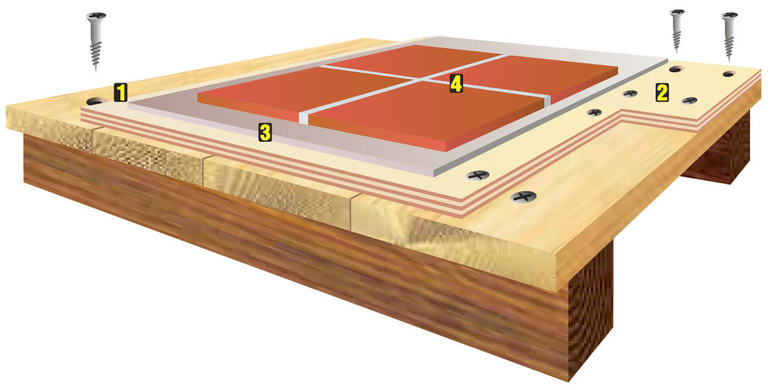

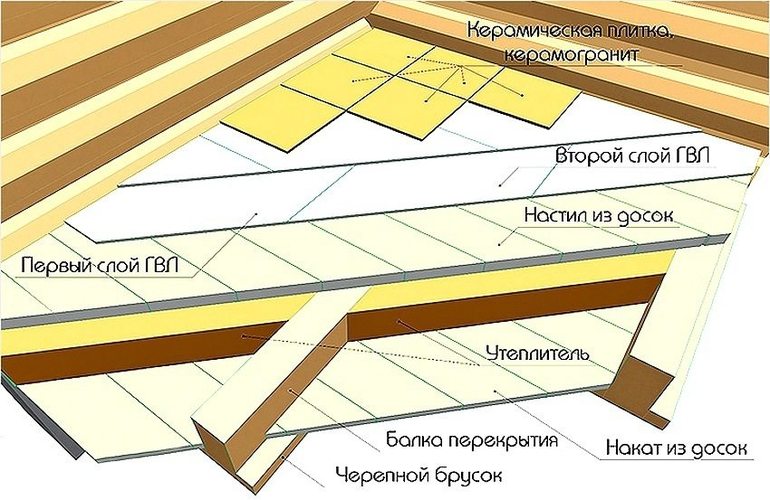

Classic floor design in houses:

- wood beams;

- draft plank or shield flooring on cranial bars;

- thermal insulation, roll protection against moisture and steam;

- clean boardwalk.

A rigid and even base is required for tiling the floor with tiles or ceramics. To reduce the voltage, alignment with fiberboard, OSB sheets, screed with reinforcement is used. A damper tape is laid along the perimeter of the base.

Preparatory stage

Inspection of the support and the top cover is carried out before laying the tiles on the floor in a wooden house. The need for such work arises due to different deformation factors of wood and ceramics. Tiles belong to the group of hard materials that need to be laid on a stable foundation. Due to its flexibility, wood adapts to small deformations.

Laying ceramics on an unsteady support will lead to cracks during operation, which will lead to additional repair costs. The stability of the wooden base is checked before work and material procurement are planned.

If a tile of small sizes is used, then it does not crack, but the seams between the tiles. Without air, moisture accumulates in cracks, pathogenic microorganisms start up, and the appearance of the floor worsens. Ceramic floor tiles have a large weight, therefore, creates additional pressure on the boards and the supporting structure.

Examination of the floor is to identify:

- squeak;

- mold, fungus, other lesions;

- shakiness of structural links;

- looseness of fasteners.

Floor repair is required if one or more of these problems are detected. Sometimes only boards are removed, in other cases, lags are disassembled and changed. Cement-sand screed or concreting is performed instead of building a new wooden structure, if it is appropriate for aesthetic and environmental indicators.

Installation of GVL sheets

Alignment of the plank floor is necessary before sticker tiles. Plasterboards in common are called dry screed. As an alternative, wood-fiber boards (MDF), wood-shaving (particleboard) are used, moisture-proof plywood, sawdust-shaving blocks (OSB) are used. These materials coordinate the plane and create additional rigidity.

Before laying the sheets, mesh reinforcement is carried out along the floor boards on bituminous mastic with the content of the sand fraction in the composition. The material is cellular material:

- from iron wire with a diameter of 3-6 mm;

- with polypropylene fibers;

- from fiberglass elements with a diameter of 2−5 mm

And also fiber is used as a reinforcing layer. The fibers of the material are made from basalt, polyvinyl chloride or glass. The reinforcement layer is 8-10 mm thick.

The sheets are attached to the boards with self-tapping screws, while a compensation gap is made along the perimeter. A damper tape is installed on the edges. Possible deformation of wood will not affect the strength of the layer from the GVL. The tile sticker is made using a polymer or composite cement-based adhesive. The seam from the solution under the ceramic tile should be no more than 2-3 mm.

Layer insulation

The use of sawdust is a common method. The material is inexpensive and can be bought as waste in a wooden workshop. Before laying into the structure, a sawdust or chip mass is mixed with lime powder and cement at a concentration of 8: 1: 1, respectively. Water is added to the mass, and the mass is dried in forms for about 2 weeks. If there is no possibility for drying, then the volume is laid out in the space between the lags on the draft boards, but the final floor is laid only after 20-25 days.

A layer of bulk expanded clay insulates the floor in a wooden structure. The material belongs to the group of hydrophobic substances, so you need to lay a high-quality waterproofing layer.

Fiberglass wool (mineral) reduces heat loss and is considered an environmentally friendly species. The waterproofing is installed above the layer of material so that it does not come into contact with the surface of the cotton wool. Mineral insulation absorbs moisture and ceases to retain heat.

Polyfoam works well in underground conditions, it is not saturated with moisture, so it is designed for a long period of operation. The material does not freeze, a layer of 5 mm is enough to delay heat loss. The disadvantage is that mice that destroy the material start up in the thickness of the foam.

Waterproofing device

Most often, roofing material, roofing, glass-roofing material is used, a polyvinyl film is used. The materials, except the latter, are fiberglass or pressed cardboard impregnated with bitumen. Top layer is sprinkled with basalt chips. Modern insulation options are component materials and at the same time protect the wooden floor from moisture, steam and retain heat.

Roll materials are available for hand assembly in the structure. The downside is the use for bonding the seams of the burner, which is inconvenient in a small room. During installation, it is envisaged that the edges of the canvases are 10-12 cm apart, and a special film is used for fixing.

Laying tiles

Tiles on the prepared base are laid according to standard technology, which is used for cladding floors from other materials. Using a notched trowel, glue is applied to the back of the ceramic, if necessary, placed on the base. The tile must be laid out in the installation position and pressed firmly to the surface.

The unit is tapped with a wooden or rubber mallet to firmly adhere the element to the surface. To lay out the adjacent tile, mounting plastic crosses are used, with their help the uniformity of the seams between the squares is observed. The quality of installation is checked by the construction level.

A small area is placed at a time, after drying, the installation is checked. If you lay out the entire area, then slight deformations of the fresh solution are possible. The adhesive dries within the time indicated on the package, before the expiration of the term, the surface must not be subjected to stress.

Repair Options

The method of preparation of the base depends on its condition at the time of work. Structural analysis of the strength and deflection of beams and wood flooring is required. A constructor in the construction field can do such design services. Independently, it is not always possible to correctly collect the loads and calculate the required section of the beams.

Good condition and construction

This technical picture is characteristic of new buildings. Sometimes the floors in the house are kept in good condition, because they are operated in gentle conditions. In this case, they immediately proceed to the preparation of a wooden coating for laying, which you can do yourself.

Stages of work:

- Elements made of wood are etched with an antiseptic. The compositions prevent mold, microorganisms and fungus.

- Secondary processing is the use of flame retardants. Substances increase the fire resistance of wood.

- Laying of the waterproofing roll layer is carried out in all rooms, regardless of the method of operation. Drops of condensate form when the structure is installed close to the ground due to the temperature difference.

- In bathrooms, hazardous humidification is provided by leaks and steam. In hot rooms of baths and saunas, a vapor barrier layer is used.

Plasterboards are laid on the floor after the completion of the insulation pie. A moisture-resistant type of material is selected, especially for the kitchen, bathroom. Installation of panels is carried out so that extended joints are not formed, but overlapped by transverse joints. Sheets are fastened with screws on wood through 150 mm.

Joints of sheets are made out with adhesive tapes or sealed with construction glue. Holes with a diameter of 10 mm are drilled on the laid area in arbitrary places for ventilation of the structure. A tile coating on gypsum fiber panels can be glued using tile glue, which is suitable for working with hot water.

Damaged flooring

Sometimes only the top flooring boards in a private house are damaged, and the lags are not yet destroyed. The top flooring is removed and replaced with quality material.

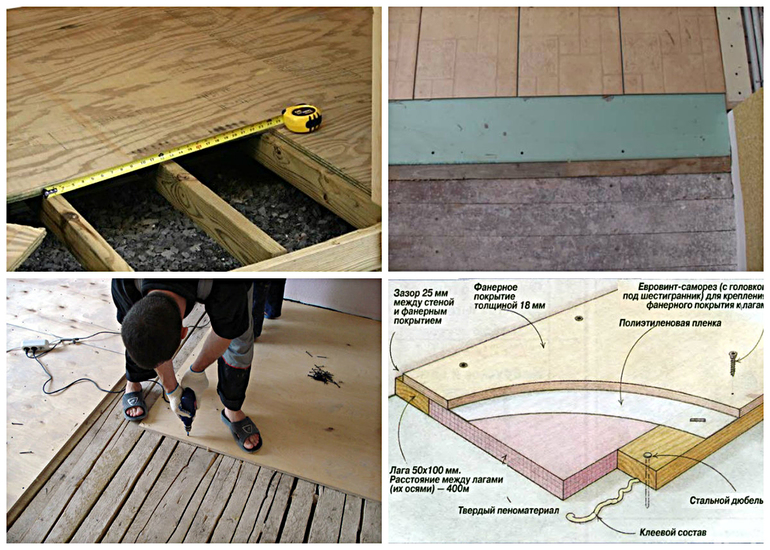

Dismantling and repair procedure:

- removal of old floor boards;

- inspection of lags to determine the integrity and quality of fastenings, checking the level of horizontalness;

- wood treatment with sealants, antipyretics;

- installation of waterproofing, protection against steam and insulation (if necessary);

- trimming in size and installation of new boards on self-tapping screws with gaps of 5-8 mm for deformation when saturated with moisture;

- GKL flooring, with processing as in the previous version.

When arranging gypsum fiber panels, a damper tape is used. It is used in rooms with an area of more than 10 m2, in rooms of l-shaped or p-shaped. The tape is made of foamed polyethylene, available in different widths. To equip a wooden base, a size of 15 cm is used. A self-adhesive substance is applied on the back side, so installation is simple.

Poor base and floor quality

Loosening and damage to the log occurs due to the sensitivity of the tree to temperature and humidity jumps. Regular drying and swelling of the material leads to loosening of the fasteners. Rotting sites appears if there is no antiseptic impregnation. Sagging floorboards are observed with an insufficient number of lags.

All these design flaws are corrected when preparing the base for the floor from tiles in a wooden house. In such a complex work, the advice of an experienced builder is useful.

Lag change operations:

- dismantle skirting boards, floorboards and logs;

- treat new constructions with antiseptics before installation;

- mark the location of beams and lags;

- mount and align the beams on the posts;

- fasten new lags;

- lay a rough floor;

- arrange insulation layers and substrate;

- lay boards;

- stick the tile.

When changing the log, the condition of the brick columns under the floor on which the structure is supported is checked. They are repaired, new ones are laid out of brick or poured with concrete. Columns are not used if the spans are small (up to 6 m), and the logs can rest directly on the beams. Structural elements are attached to the supports and connected to each other, then proceed to the next step.

The distance between the logs is made from 50 to 80 cm, it depends on the length, thickness of the rough and finish boards and load.After laying the auxiliary floor, lay insulation layers and mount the upper boards. A substrate is made of fibrous gypsum sheets for laying tiles on the floor in a wooden house. The technology of work must not be disturbed in order to achieve a good result.

- How to choose a vacuum cleaner taking into account the characteristics of the house and coatings?

- What to look for when choosing a water delivery

- How to quickly create comfort at home - tips for housewives

- How to choose the perfect TV - useful tips

- What to look for when choosing blinds

- What should be running shoes?

- What useful things can you buy in a hardware store

- Iphone 11 pro max review

- Than iPhone is better than Android smartphones