Equipment and household installation for powder coating products

Now special equipment for painting metal products with powder is becoming more and more in demand. This is a progressive method that does not allow minor imperfections to form on the surface, for example, stains, streaks, irregularities of the coating. This technology has practically no drawbacks.

The essence of technology

The main difference of this method from others is that the paint is applied in a dry form on the surface to be treated. In general, the process involves applying the powder and fixing it.

During the spraying of a special powder on the surface of the processed material, all its particles receive an electric charge, which is opposite to the charge of the object. Because of this, attraction occurs. This is how the powder adheres tightly to the surface.

But the object is not yet ready for use, since it is necessary to fix the structure and color. For this, a baking method is used, which involves heating a painted object in a special oven. The heat begins to melt the powder. It turns into a solid film.

This technology is almost always used during the painting of metal structures.

Advantages, disadvantages and scope

Powder painting equipment is used not only by professional builders. Increasingly, it is used by home masters. This method has significant advantages, including environmental friendliness and profitability. Conventional liquid paint can not boast of this.

In the composition of powder paint there are no solvents that are quite dangerous for human health. Also, this material is less consumed. Fallen particles after spraying can be collected and used again for painting other objects.

Main advantages:

- During operation, there is no unpleasant odor that liquid paint has.

- Dry material cannot ignite spontaneously.

- The painting procedure takes a minimum amount of time.

- Upon receipt of an unsatisfactory result, the surface is easily repainted.

- Painting is carried out in one step, if the installation for painting is of high quality.

- Dry paint lays well even on uneven surfaces.

- The final coating is smooth and uniform.

- A primer is not required before the procedure.

- Dry paint does not deteriorate due to temperature changes. Also, the coating is not susceptible to corrosion processes.

But technology has its drawbacks. They are quite significant, so in everyday life paint plants are rarely used. Among the minuses are:

- Powder paint is not used for plastic and wood.

- If you need to cover a large object, you must use a large furnace for polymerization.

- A thin layer is quite difficult to obtain.

- The high cost of equipment.

The scope is not limited to metal structures. You can paint concrete, stone, tempered and armored glass. The applied layer does not fade in the sun, does not react well with acids and other chemicals, almost does not scratch, does not collapse in frost. Therefore, powder paint is used:

- In shipbuilding.

- By production of cars, motorcycles and bicycles.

- For coloring household appliances.

- When creating monuments.

- For painting individual elements of bridges and towers.

Powder paint is used in many industries. Every day the scope is only expanding. For the production of such a material is the best option.

Painting tools

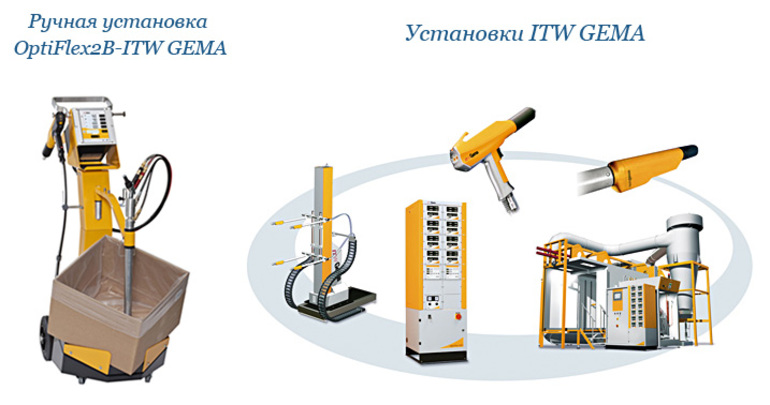

For the application of powder coating technology, certain equipment is required. Work requires a spray gun and a chamber that is designed for baking paint.

A sprayer is needed for spraying a powdery coating material. There are manual and automatic devices. The polymerization is carried out in a baking chamber. Thanks to this process, the paint gets its performance properties after turning into a film.

If you plan to use powder technology only once, then it makes no sense to purchase a special expensive furnace. It can be replaced with a conventional oven.

To carry out painting in accordance with all safety rules, it is necessary to ensure:

- Good ventilation.

- Adequate lighting.

Especially need to pay attention to ventilation. If the room is poorly ventilated, there is a high probability of harming your health. If it is not possible to create the necessary conditions, then it is better to carry out work on the street or in a garage with open gates.

Good illumination will allow you to apply a uniform and high-quality coat of paint. Better to use fluorescent lamps. It is undesirable to provide incandescent lighting. During spraying, particles of paint will settle on them.

After finishing work, you need to think about how to collect the remaining powder. You can pre-lay the film on the floor, but it is better to use a cyclone vacuum cleaner. You can not use a conventional vacuum cleaner, as it will become clogged almost immediately.

Surface preparation

To prepare the metal surface for painting, you will have to be patient. It will take a lot of time and a lot of work. But this stage is extremely important, since the result depends on it. It is necessary to pay special attention to this stage.

To prepare a metal surface, do the following:

- Thoroughly clean the part of all contaminants.

- Remove traces of fat. For this, you can use ordinary alcohol or a solvent.

- To process a surface with any anticorrosive material.

- Apply special phosphating agents to the metal. This allows for increased grip.

Pretreatment is carried out using chemical compounds or manually. If the work is done on its own, then you will need to prepare a grinding disk and metal brushes. You will also need to moisten a clean rag in a solvent and wipe the painted surface.

Processing using chemical compositions involves the use of solvents, acids and alkalis. When choosing a product, you need to proceed from the type of material that will be painted, the complexity of contamination and the size of the workpiece.

When processing, it is also worth using a conversion sublayer. This will reduce the likelihood of moisture and dirt getting under the paint, which will protect it from peeling. So the initial result will remain for a long time. Phosphating agents are applied to the conversion sublayer.

Also, during preparation, do not forget about passerization. The meaning of the procedure is that chromium and sodium are applied to the metal. This protects the surface from corrosion.

After completing this step, the metal must be rinsed and dried. Only now can we start staining.

Powder atomization and polymerization process

It is necessary to take the spray device and begin to apply the powder evenly on the previously prepared surface. It is advisable to protect the working area with a screen. Otherwise, the paint will scatter throughout the room.

After spraying, you can proceed to fixing the paint in a special furnace.It should be borne in mind that the melting point of dry powder is from 150 to 220 degrees Celsius. High-quality polymerization involves baking the workpiece in an oven for 30 minutes. In some cases, the duration and temperature are different. It all depends on the object being painted, the type of paint and the type of stove.

When operating the equipment, it is necessary to ensure that the part is baked at a constant temperature. Only in this way can a uniform melting of the powder be achieved, which will make it possible to obtain an even and accurate layer.

After polymerization, the workpiece must be removed from the oven and allowed to cool on its own. On this powder painting can be considered complete.

The standard method of staining using liquid materials has many significant drawbacks. Because of this, dry paint has been used recently in construction and in everyday life. This method is much more productive, but it requires the presence of special equipment and certain skills. However, the costs in any case will pay off, since this technology allows you to get better coverage, as well as reduce physical activity.

Equipment Tips

Of course, a person during the selection of equipment will be guided by its quality and cost. But it is worth considering other factors. Among them are:

- The room where the installation will be located. The space should allow for compliance with safety regulations.

- If it is not possible to allocate a sufficient area, then it is worth using only small-sized installations.

- Type and size of products to be painted.

- Stoves are gas and electric. The choice depends on the features and usability.

- If the color of the paint will often change, it is better to buy a spray with a two-stage system.

- When choosing a sprayer should be based on the amount of work. For small ones, it is better to take a tribostatic device, and for large ones, an electrostatic device.

- It is better to purchase equipment from companies that provide warranty and after-sales service.

not universal. It is not suitable for all surfaces. Therefore, before using the technology, you should figure out how much it will be profitable.

- How to choose a vacuum cleaner taking into account the characteristics of the house and coatings?

- What to look for when choosing a water delivery

- How to quickly create comfort at home - tips for housewives

- How to choose the perfect TV - useful tips

- What to look for when choosing blinds

- What should be running shoes?

- What useful things can you buy in a hardware store

- Iphone 11 pro max review

- Than iPhone is better than Android smartphones