Do-it-yourself warm water baseboard

Central, electric, air - various heating systems, invented and developed today, allow any owner to choose the best option for their home. But along with proven systems, there are also new products on the market that immediately attract attention. A vivid example is a warm baseboard. In Europe, such an option for space heating has been known for two decades and is actively used both in residential buildings and in offices. The system is quite simple - a plinth of metal is mounted around the perimeter of the room, inside of which there is a heating element. Heat is generated by thermal radiation. Like any new product, installing such a system by professionals is expensive. But the availability of materials and ease of installation will allow anyone to make a warm water baseboard with their own hands.

to contents ↑Skirting board advantages

The technology, which is fundamentally different from traditional heating systems, looks like an ordinary decorative element from the outside. She received popular love, thanks to her filling:

- A warm do-it-yourself skirting board is equal in thickness to the traditional analogue, but the height is a little more - 12-15 cm. This is done for the convenience of mounting the heating system inside the element.

- The decoration is mounted at the junction of the floor and walls around the entire perimeter of the living room, organically fits into any interior.

- The principle of operation is simple - electricity or coolant heat the tubes, and they, in turn, give off heat to the external aluminum casing.

Important! To create a warm plinth with your own hands, only non-ferrous metals are used, which avoids the appearance of corrosion and maximizes the thermal conductivity of the plinth.

The pros do not end there:

- Installing a warm baseboard allows you to get rid of uncomfortable batteries - the dream of many owners. Nothing will prevent you from realizing any idea of an interior designer. Ugly batteries do not have to be hidden in cabinets, behind screens or curtains.

- Such a system allows you to increase the life of your furniture, because, for example, a cabinet standing next to a conventional converter, because of the hot air, quickly dries up.

- A warm skirting board with your own hands can be both a full-fledged heating method, and an auxiliary one. This element can not be placed around the entire perimeter of the room, but only where additional heating is needed. This reduces energy consumption, while not reducing the efficiency of the device.

- An innovative heating system can be mounted not only in a new apartment, and not only during repair. Its installation is possible even months after the completion of construction and repair work.

- Do-it-yourself warm skirting board can be used in any room. They are suitable for living rooms, bedrooms and offices perfectly warm glazed verandas, terraces, conservatories, balconies and loggias, can be installed in the bathroom and toilet, safe even for a children's room.

Another great advantage of a do-it-yourself warm skirting board is that it does not create a “heat pad” under the ceiling. The entire space of any room is heated evenly:

- Standard heating systems work in such a way that hot air certainly rises. In this case, drafts on the floor are possible.If the room is small, then this is not so noticeable. But, for example, in country houses this difference is quite large.

- The skirting system acts in such a way that heat is given not only to the space, but also to the walls. This advantage is useful to owners of private houses, whose walls often freeze, and residents of corner apartments of high-rise buildings.

Important! There are not so many shortcomings of a warm plinth with your own hands:

- This system cannot be completely turned off like a battery; no regulator is provided.

- The cost of this new product can not yet be called budget.

But many people prefer this system rather than a warm floor, because for the installation of a warm skirting board you do not need to prepare a concrete screed, the modular design of the system is very mobile. At any time, you can take and transfer it to another room.

to contents ↑Skirting device

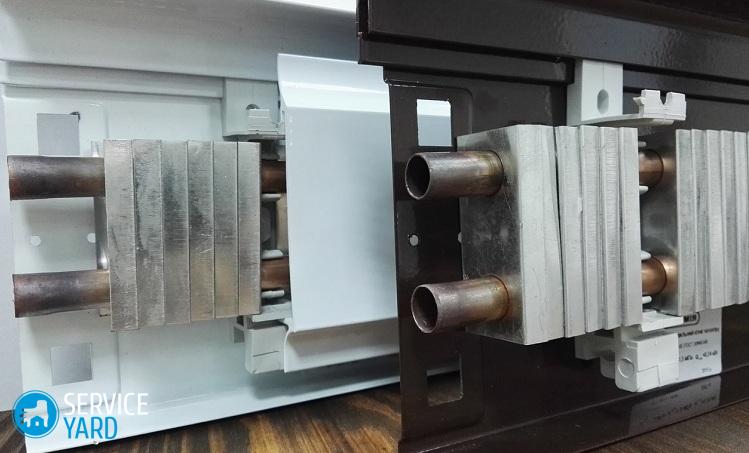

As we already said, a do-it-yourself warm baseboard externally is a collapsible metal box of three aluminum strips with a total height of 14 cm and a width of 3 cm:

- Inside the aluminum cladding, heat transfer heating module is fixed on special bracket-holders. These are two copper pipes with brass plates tightly mounted on them.

Important! Copper, as you know, has high heat dissipation and high resistance to corrosion, but has a high price. Aluminum also transfers heat well, but costs a lot less. Therefore, the combination of copper + aluminum is used in many heating appliances and has proven its effectiveness.

- Between themselves, the heating modules are connected using crimp nuts or fittings designed for copper brazing.

- Water is supplied from the boiler by reliable polymer pipes, usually polyethylene.

- To connect the heat exchange modules in the corners and loop loops, special rotary pipes made of cross-linked polyethylene are designed, as well as corner connectors are used.

- From the visible part, decorative joints of the aluminum profile at the corners and ends are closed with plastic elements - corner or end caps.

By the method of heating, a warm plinth with your own hands is divided into water and electric systems:

- Special low-temperature heating elements are inserted into the warm baseboard. They heat up to a maximum of 60 oC. This power for residential premises will be enough, because one running meter produces about 180-280 watts.

- Warm baseboard water works on the basis of a single heating circuit. If there are several circuits, it is worth connecting a collector or comb. You can use the most ordinary model or with flow meters - the owner decides this question himself. Heating modules with a water heating method are dialed based on the required power for a specific thermal pressure of the system.

to contents ↑Important! First of all, remember that the maximum length of the circuit should not exceed 12 meters. When planning a system do-it-yourself warm skirting board this moment should be taken into account.

Skirting Installation

The main element of the system - the baseboard, can be obtained in two different ways.

For the first you will need copper unannealed tubes. The diameter most suitable for these purposes is a maximum of 20 mm. It is also worth stocking up with roofing copper - there are no special requirements for the material.

The procedure for the work is as follows:

- Sheets of roofing copper are cut into strips 15 cm wide - this is the most optimal size. These works should be carried out using a grinder.

- The edges of the resulting strips are flanged over the entire length, the bending angle should be straight. The width of the shelf should be about 7-8 mm.

Important! Strips should not be made longer than 3 meters, otherwise - you yourself complicate the work, longer workpieces are simply inconvenient to mount.

- Copper tubes, the ends of which are slightly bent to the side, are soldered to the inside of the case. Bends should be done, again, for the convenience of installing a warm baseboard.

- Standard hoses or sleeves are fixed on pipes with ordinary clamps - for supplying coolant. Their diameter should not exceed 12 mm.

- Such warm skirting boards are attached to the wall with their own hands using conventional mounting clips, selected by the diameter of the tubes.

In the second case, in order to make electric skirting boards do-it-yourself, standard aluminum profiles used in the installation of drywall can be used. Assembly operations in this case are carried out according to the following scheme:

- First, on the basis of the workpiece, small holes are made from below and from above that are necessary for attaching the profile to the walls.

- Then the copper tubes are laid inside the profile and secured with aluminum wire.

- After that, the entire resulting structure is mounted on the wall so that the tubes are located one above the other.

to contents ↑Important! It is most convenient to use standard connectors to assemble individual fragments into a single system. You can use the same profiles painted in the corresponding tone walls as the front panels of a warm skirting board with your own hands.

Quality and manufacturers of warm skirting boards

There are both European manufacturers of systems and domestic in the building materials market. With prices and quality as usual:

- Europeans are beautiful, reliable, expensive;

- domestic - cheaper, but worse done.

Important! The difference is not only in appearance. There is a problem with the occurrence of squeaks and clicks in the system during sudden heating and cooling. This problem is typical for the combination of two metals; different thermal expansion provokes the occurrence of such an effect. Europeans have been producing this technique for decades and have learned how to deal with it. Ours so far only strive for this.

The best results were achieved by two manufacturers.

Mr. Tektum

The most popular today is the company “Mr. Tektum. " The heating system of this brand is assembled and manufactured in Russia. This is the best option in terms of price and quality. Due to the fact that system elements are not imported, but are manufactured locally, the price is much lower than foreign analogues.

Among the main advantages are improved thermotechnical and hydraulic characteristics of the do-it-yourself warm skirting board. They are based on the manufacture of an aluminum box of a special shape, the presence of rotary angle pipes, corrugated stainless elements and accompanying fittings.

Thermia

The heating system of the Ukrainian company "Termiya" deserves attention in connection with the possibility of more efficient energy savings. Products of this brand differ from the others in that they have a balanced heat transfer and low thermal tension. What does it give?

First of all, after installing a warm baseboard, the room warms up evenly and does not allow stagnation of warm air near the ceiling to form. Low thermal tension makes it possible to arrange furniture as you want, and not based on the position of the baseboard. Furniture sets do not overheat and do not affect the overall heat distribution in the room.

to contents ↑Important! The degree of savings on heating, according to monitoring, ranges from 20% to 40%.

General scheme of work

Before installing a warm baseboard, it is worth calculating the required power of the system and determine its type. The number of modules that will heat your room depends on:

- general insulation of the house;

- total glazing area;

- climate of the region.

The general installation of a warm skirting board, regardless of the type selected, is a fairly simple process that can be divided into the following steps:

- Before installation, they mark the line for the installation of panels, a warm baseboard should be located at a height of 1 cm from the floor.

- A rear panel is applied to the reference line and marking is made for mounting holes, which are then drilled by a punch.

- The panel is fixed with self-tapping screws with plastic dowels or glue. On the back of the strip there are stops that provide the necessary clearance of 15 mm between the wall and the device.

- A heat-insulating tape is glued between the wall and the heater body, its edges are carefully cut.

- Mount brackets for convectors. For this, dowels are used, the installation step is 40 cm. A fluoroplastic gasket is inserted into each bracket.

- For angular docking elements of a warm skirting board, do-it-yourselfers prepare and install the upper parts of the corners in advance.

- Hang the panels of a warm skirting board.

Features of the installation of the electrical system

Do-it-yourself installation of a warm electric baseboard has its own characteristics. Externally, such a system does not differ from the water system, but the filling is completely different:

- A heating element is inserted into the lower copper tube inside the heating element, and a heat-resistant silicone-insulated power cable is laid inside the upper copper tube.

- The power supply for such a warm skirting board is switched by a thermostat with an air sensor, which maintains the required room temperature by turning the system on and off.

- A characteristic moment of the electrical system is its complete electrical safety. Contact points are first insulated with heat-shrinkable hoses to protect them from moisture, and special boxes protect them from mechanical stress.

Important! Despite this protection, it is still not recommended to install the electrical system in a room with high humidity, as, indeed, any electrical appliances.

- The electrical system of a warm skirting board with its own hands has a power of TENOV 200 W per linear meter and is connected to a standard power source. As a rule, this is a conclusion from the mounting box at a height of 4-6 cm from the level of the “finished” floor.

Important! As practice shows, such a system is most often connected where it is possible to supply the necessary power. It is also popular at facilities where a local solution to the problem of additional heating is needed, for example, on moist corner walls, where there is a risk of mold or condensation.

Features of the installation of the water system

Before starting work on installing a warm water plinth with your own hands, it is mandatory to determine the number of sections of the water heater. When calculating, it should be taken into account that the length of one skirting board should not exceed 12 m, otherwise it can cause large heat losses:

- Work begins with the removal of plastic pipes from a heat source - an individual boiler or central heating system. To do this, measure the distance from the distributing source to the first section of the warm skirting board with your own hands. Then cut off the pipe parts of the required length and connect them to the heating system through the floor or wall.

- Prepare a heating radiator - remove the two extreme lamellas and put the connecting nuts on the copper tubes.

- Use the fittings to connect the copper tubing to the outlet plastic tubing. Secure rubber gaskets between nuts and fittings. At the corner joints and ends of each circuit, install rotary pipe elements.

- Stick heat-reflecting tape to the inner surface of the front panel. Using the brackets and screws, fix the panel on the upper and lower back rails.

- Install the decorative elements of a warm skirting board with your own hands - corners, plugs, caps for the heads of self-tapping screws.

After connecting a watery warm baseboard, crimping, balancing and washing the contours is done with your own hands. Also, do not forget about the automation settings. After that, you can start the system in work.

to contents ↑Stock footage

In conclusion, it is worth saying about the feature of a warm skirting board with your own hands. This system is effective in homes with permanent residence.At a minimum, with constant heating in low temperature mode and periodic increase to a comfortable level. The fast heating mode is not their area of application, the power is not so great. And the rest, as you have seen, the system is a fairly simple installation and operation.

- How to choose a vacuum cleaner taking into account the characteristics of the house and coatings?

- What to look for when choosing a water delivery

- How to quickly create comfort at home - tips for housewives

- How to choose the perfect TV - useful tips

- What to look for when choosing blinds

- What should be running shoes?

- What useful things can you buy in a hardware store

- Iphone 11 pro max review

- Than iPhone is better than Android smartphones