DSP slab - application

- Cement-bonded particleboards - composition and production

- Application

- Characteristics of DSP slabs:

- Advantages and disadvantages

- DSP in insulation works

- Floor application

- The choice of cement sheets for the floor

- Preparation for the coating device from DSP

- Floor arrangement with DSP

- DSP floors - laying nuances

- Technical characteristics of DSP slabs - application for formwork

- Application of DSP panels for exterior decoration of a house:

- Stock footage

If during construction work it is impossible to create an ordinary cement screed, and you are limited in time, then a cement-bonded particleboard is perfect. The use of such building materials for the floor allows you to quickly create a flat surface. At the same time, the flooring will be of high quality and durable. In this article, we will consider a DSP slab - application, features and characteristics of the material.

to contents ↑Cement-bonded particleboards - composition and production

The name of the cement-bonded particleboard fully reflects the composition of this material. So, DSP is made of a mixture, which includes wood shavings and components of cement compositions.

Building materials are characterized by the following composition:

- water - 8.5%;

- wood shavings having fractions of various sizes is 24%;

- special additives in an amount of 2.5%;

- Portland cement, which represents 65%.

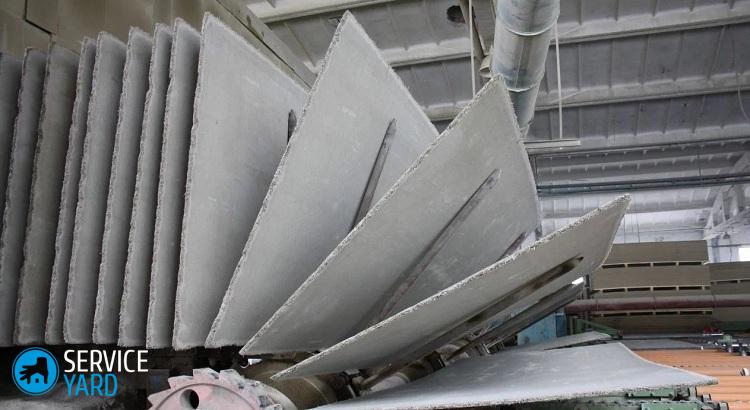

The manufacturing process is relatively simple, cement chipboards are made as follows:

- Special aqueous solutions are loaded into special mixers, which consist of various salts, water glass and aluminum.

- Then, wood chips with included fractions of different sizes are slowly added to these solutions, as a result, the raw material is mineralized.

- Cement is mixed into the resulting composition and a little water is added.

- The resulting mass is thoroughly mixed until uniform, and then sent under a powerful press.

As a result of the production chain, a fairly thin cement-bonded particleboard is formed. The presence in the composition of a large amount of cement creates a fairly durable material. Inside the chip, the chips are larger than on the outside. Due to this, a smooth surface condition of the finished material is achieved. An important factor is that during production, voids do not form inside cement-bonded particleboards.

to contents ↑Important! As a raw material, wood chips are also used in the production of fiberboard, particleboard and OSB boards. The manufacturing technology of these materials is similar.

Application

DSP slabs are widely used in construction:

- They are used as decoration of the facade walls of buildings.

- They form various partitions in the interior.

- The material can be used for interior decorating, as well as for restoration purposes. Moreover, it is perfect for both private homes and apartments.

- The use of cement-bonded particleboard allows you to abandon the time-consuming process of pouring cement screed, which is used to create and level the base. This type of building material significantly reduces labor costs, while saving the family budget, which is planned to level the floors before laying the finish coating.

to contents ↑Important! Cement bonded particleboard has a high environmental performance, as it is made from natural materials and it has virtually no additional chemical ingredients.Therefore, experts advise it to be used both in industrial facilities and in residential premises.

Characteristics of DSP slabs:

- Cement bonded particleboard is a material of a completely new category, which is characterized by high strength, long service life, and a certain indicator of moisture resistance.

- This material is characterized by excellent heat-saving and soundproofing properties.

- Thanks to these features, TsSP slabs have taken a strong place in the construction field and are widely used in repair work.

Important! Compared with chipboard, which is usual for many consumers, it is found that the cement-bonded particleboard is three times stronger in characteristics and has high resistance to various loads and physical influences.

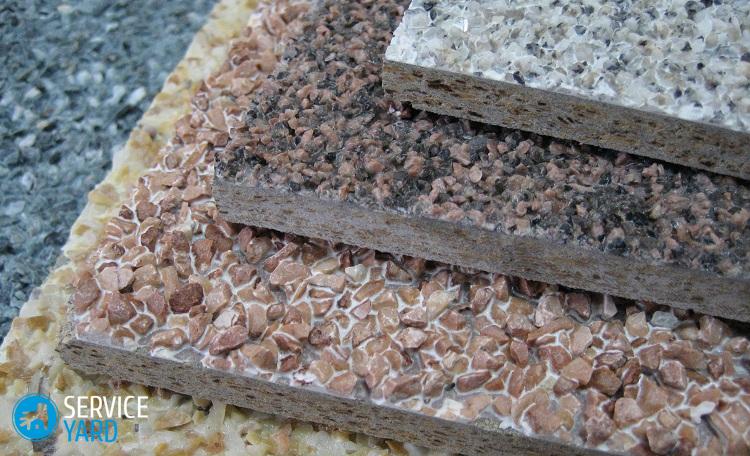

- A slab based on cement and chips has a fairly high density of one cubic meter, which is 1300-1400 kg / m3.

- The material is characterized by a moisture content of about 6-12%, while it is 100% not protected from water, but even in contact with the liquid during the day, the swelling of the plate should not increase more than 2%.

- The stove is rough and smooth to the touch. Very often, this indicator depends on the grinding method. If the roughness level is about 80 microns, then the cement bonded particleboard does not need to be polished.

Important! When choosing a plate, operating conditions and requirements for the final results are taken into account. So, for example, indoors, as a rule, smooth plates are used, and outside you can use rough building materials.

- Finishing with cement-bonded particle boards is very simple. On the surface, you can lay out any kind of floor finish or without any problems apply varnish, plaster, paint.

Advantages and disadvantages

Compared to other similar materials, cement-based slabs and chips have both advantages and disadvantages.

Consider the advantages of DSP:

- mold, fungus does not settle on the plates;

- DSP sheets for the floor are made from natural components and is environmentally friendly, the material does not contain asbestos and formaldehyde-containing substances;

- the main advantage is not the hygroscopicity of the material;

- DSP slabs can resist fire for 50 minutes - since the material is 100% non-combustible, it is perfectly used in any room;

- due to the multilayered material, DSP boards are characterized by considerable strength, good performance is also noted at the time of pressure from the end of the plate and from other sides;

- at significant temperature differences, cement-bonded particleboards do not lose their operational properties;

- the plate does not respond to chemical influences;

- quite acceptable cost;

- simple installation;

- no additional alignment of surfaces is required;

- a plate based on cement and chips perfectly resists decay processes;

- the material is characterized by high thermal and noise insulation properties;

- the material is impervious to water - so a cement bonded slab can absorb a maximum amount of liquid in a full day, which corresponds to 16%.

Important! When installing a water system of warm flooring, the use of cement-bonded particleboards is recommended. In this case, it is possible to form an additional air gap, which is located between the finish coating and heating, which significantly improves the result of the work performed.

In addition to the pros, DSP has also disadvantages:

- the processing of the material is accompanied by the presence of a large amount of dust, therefore, when cutting plates, it is necessary to use a respirator, goggles, which protect the organs of vision and breathing and not harm them;

- the material has a large mass, which greatly complicates the work with it.

DSP in insulation works

What is DSP in construction? Basically, DSP slabs are used when warming buildings and structures.This material is sheathed outside the building. Using nails or self-tapping screws, fixing is performed.

Since cement-building slabs are an environmentally friendly material, flooring and walls can also be cladded indoors. Inside the buildings, the sheathing process is similar to the outside, while the material is fixed on a wooden or metal crate using self-tapping screws or nails. But sometimes situations arise when adhesive mastics are used. After installation, finishing is done.

to contents ↑Floor application

Cement chipboards are often used to create a rough floor:

- Most often, the material is used, implying that in the future ceramic tile will be laid on it, which is the most demanding coating on the evenness of the base.

- In addition, DSPs are in demand for the installation of floor coverings on a soft basis and for the process of pouring three-dimensional floors.

- Often, cement-bonded particleboards are laid out under the carpet, laminate, linoleum.

Plates are mounted on logs or laid on a flat wooden or concrete base. The material has a long service life, under the conditions of proper installation it is able to withstand significant loads.

to contents ↑The choice of cement sheets for the floor

The choice of cement-bonded particleboards is carried out, depending on the conditions in which the material will be used, and on the installation technology:

- If you want to lay on the logs, then use slabs having a thickness of 20-26 mm, which are perfect for a rough base.

- In the case of installation work directly on the ground, use plates of 24-26 mm.

Although in general, when leveling floors use any DSP slabs.

Important! Even at temperatures below zero, cement-bonded particleboards can be laid.

When installing the floor surface, the following requirements are made for the characteristics of cement-bonded particleboards:

- density is more than 1300 kg / m3;

- humidity ranges from 6 to 12%;

- surface roughness is 80 microns;

- tensile strength is characterized by 0.4 MPa;

- moisture absorption corresponds to 16%.

Preparation for the coating device from DSP

Before proceeding with the arrangement of the rough coating with cement-bonded particleboards, the floor base should be properly prepared:

- If the laying of the material takes place on a wooden base, then it is necessary to carefully inspect the boards, while old or decayed planks must be removed and replaced with new ones. It is important to seal all the cracks with putty and prime the wooden base, as a result - there will be better adhesion to the glue that will be used when installing the plates.

- If installation work will be carried out on a concrete base, then it should also be carefully inspected for damage, and if necessary, it needs to be repaired. In the presence of strong horizontal deviations, it is necessary to use cement mixtures, with which equalization is carried out.

- If laying is carried out on the ground, then a preliminary leveling of the surface is mandatory, which can be covered with a sand-gravel mixture of about 20 cm thickness and carefully compacted.

- With the planned installation of the base on the logs, the installation of supports under the logs occurs on the ground and heat and waterproofing are laid. The distance between the supports varies from 0.5 to 1 m, while the thickness used for logs affects this indicator.

To work with cement-bonded particleboards, the following materials and tools should be prepared:

- the required number of DSP boards;

- log for logs having a section of 150x100 or 50x100 mm;

- a hacksaw that is used as a sawing tool;

- antiseptic solution for timber;

- tape measure and pencil, which are used for making measurements;

- fixing material;

- materials for insulation and waterproofing;

- drill.

Floor arrangement with DSP

Consider how to lay a DSP on a wooden floor:

- We lay the insulation layer under the logs, which we install parallel to the walls, while the distance from each other corresponds to 30-40 cm.

- We install the transverse bars, thus creating a crate. With the help of metal screws and corners, we make a connection between wooden blocks.

- The space that is between the lags is filled with insulation material.

- Across the longitudinal logs, we lay the plates of the DSP of the desired size. At the same time, we control that the width of the piece of material is slightly less than the width of the balcony by 5-10 mm.

- Using screws, we fix the plates on the logs. Using the adhesive composition, we close the gaps between the cement-bonded boards.

DSP floors - laying nuances

In order for the floor base to be of the highest quality, it is important to adhere to some recommendations when installing cement-bonded particleboards:

- a wooden log for logs is necessarily processed with compounds that prevent the process of decay, while special compounds can be replaced with machine oil;

- in the case of concrete screed during the installation of slabs, a beam having a smaller cross section of 50x50 mm can be used as a log, thus saving usable space;

- when installing the lag, it is required to monitor their level, which should be strictly horizontal;

- Before proceeding with the installation, the DSP boards should be laid out in lags, which will allow you to orient yourself and determine which ones you need to trim if necessary;

- before use, the adhesive should have a uniform consistency and mix well;

- the presence of compensation clearances along the walls avoids deformation of the base of the DSP slabs;

Since the cement-bonded particleboard has a large mass of sheets, it is more advisable to acquire an assistant in the process of work.

to contents ↑Technical characteristics of DSP slabs - application for formwork

When creating formwork, DSP sheets for the floor play an important role. So, the use of such panels has a number of advantages:

- the ability to install more reliable designs;

- Significant saving of time required for work;

- a significant reduction in financial costs required for construction work.

Formwork made of cement-based slabs and shavings is a complete architectural element that does not require additional cladding. Such plates very often find application in the creation of window sills. At the same time, a quite adequate price goes well with the original appearance and acceptable technical characteristics.

to contents ↑Application of DSP panels for exterior decoration of a house:

- Buildings finished with facade panels based on cement and shavings have an impeccable view. When using a cement-bonded particleboard under a brick, houses look very attractive and stylish.

- Plates of this type have such properties, due to which they do not need to be coated with special compounds, which is very convenient for decoration.

- The thickness of the panels for exterior decoration should have a maximum value so that the protective layer is as thick as possible. Thanks to this, it becomes possible to create an additional barrier between the foundation and the external impact, which manifests itself in the form of rain, strong wind and other negative factors.

Stock footage

In the modern market there are various types of building materials. According to their technical characteristics, not many are able to compete with slabs based on cement and chips. The use of DSP slabs is so popular that it penetrates almost all construction sectors. The environmental friendliness of the material and the quite adequate price certainly leave this material out of competition.

- How to choose a vacuum cleaner taking into account the characteristics of the house and coatings?

- What to look for when choosing a water delivery

- How to quickly create comfort at home - tips for housewives

- How to choose the perfect TV - useful tips

- What to look for when choosing blinds

- What should be running shoes?

- What useful things can you buy in a hardware store

- Iphone 11 pro max review

- Than iPhone is better than Android smartphones